What is a programmable logic controller? & What is delta PLC & Ladder Programming

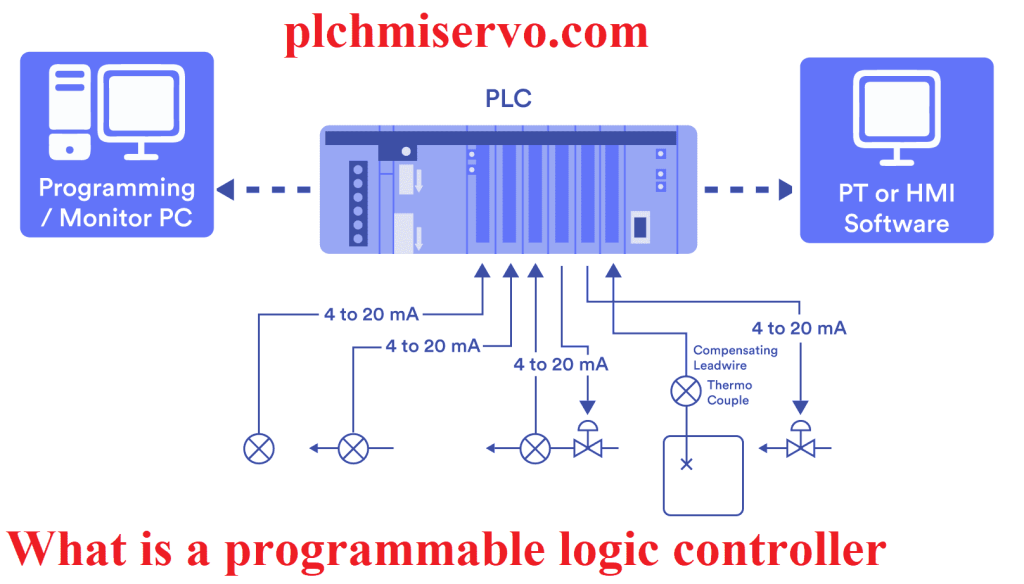

What is a programmable logic controller? A Programmable Logic Controller (PLC) is a durable computer utilized in industrial automation to streamline processes, control machines, and manage production lines. By gathering input from sensors and devices, the PLC processes this data and activates outputs based on predefined parameters. Additionally, PLCs can track runtime data, initiate and halt processes, issue alerts in case of malfunctions, and offer a versatile control solution adaptable to various applications. One distinguishing factor of PLCs compared to industrial PCs and microcontrollers is their input and output (I/O) modules, which connect the CPU to the machine. These modules enable the PLC to receive information from sensors, switches, and meters, and trigger actions through relays, lights, valves, and drives. Relying on the inputs and outputs, a PLC is capable of monitoring and recording run-time data like operating temperature or machine productivity, automatically start and stop systems, create alarms if a machine functions poorly, and more. Users have the flexibility to customize the PLC’s I/O configuration to suit their specific needs. To interact with the PLC in real-time, users rely on a Human Machine Interface (HMI), which can range from basic text displays with keypads to advanced touchscreen panels. These interfaces enable users to input and review information efficiently, enhancing the overall functionality of the PLC system. Furthermore, PLCs incorporate communication capabilities to interface with different systems, such as SCADA systems for data monitoring and analysis. The availability of various ports and communication protocols ensures seamless connectivity between the PLC and external devices.

What are the different types of PLC & What is a programmable logic controller?

The types of PLC may be classified agreeing to a few parameters. When it comes to the types of PLC, these two are the foremost common among all the classifications accessible.

1. Fixed/Integrated/Compact PLC

This PLC is Fixed I/O PLC. “Fixed I/O” actually stands for Settled “Input/Output”. Once you purchase Compact PLCs, you’ll take note that the input segment and the yield segments of the PLC are coordinates into the microcontroller itself. This implies that each type of yield or input is settled and is decided by the producer. Besides, this type of PLC may not extend the number of inputs and outputs.

2. Modular PLC

The secluded PLC may be a type that permits numerous developments of the PLC framework through the utilize of modules, consequently the term “modular”. Modules deliver the programmable rationale controller extra highlights like expanded number of I/O units, and they are ordinarily simpler to utilize since each component is autonomous of each other. The control supply, communications module, Input/Output module are all partitioned to the real microcontroller so you have got to manually connect them to each other to make your PLC control framework. A type of Modular PLC is the rack-mounted or rack mount PLC. In a rack mount PLC, the communications module of the PLC dwells within the rack itself, so all associations are centralized.

Types of PLC according to Measure

+Mini PLC: Scaled down PLCs have more often than not have 128 to 512 I/O focuses which are as of now a LOT for a control framework. For little control framework that’s as it were predicted to scale up a small bit, Scaled down PLCs are perfect to utilize rather than bigger PLCs (over 512 I/O focuses).

+Micro PLC: They are most commonly utilized in exceptionally little computerization or control frameworks like entertainment rides. Since entertainment rides require that the controls are close the ride itself so this dispenses with the prerequisite that there ought to be a “Central PLC” for all the rides within the beguilement stop.

+Pico/Nano PLC: Pico PLCs have less than 15 I/O focuses. More often than not, they are seen in PLC coach frameworks since they are exceptionally simple to utilize (and ordinarily comes with a show board) and they don’t see threatening to fledglings who need to know the nuts and bolts of PLC first. The thing that is truly alluring in Pico/Nano PLC gadgets is the effortlessness and compactness as they are ordinarily fair the measure of your hand.

+Safety PLCs: The safety or security PLC could be a uncommon type of PLC that acclimates to the IEC 61508 – Useful Security of Electrical/Electronic/Programmable Electronic Safety-related Frameworks. Basically, this type of PLC functions rather like the typical logic controller but that it nearly does not come up short. It is more costly than the typical PLC since of the included security circuitry. But it is more helpful within the long run to use safety PLCs instep of normal PLCs.

What is delta PLC?

Delta PLC, developed by Delta Electronics, is a type of programmable logic controller (PLC) that is designed to control industrial processes and machinery with precision and flexibility. Delta PLCs help to orchestrate operations with durable, high-speed, and trusted applications across multiple machines of industrial automation. Delta PLC has made significant strides forward since its inception to meet the evolving requirements of the industry. To fully comprehend the significance of Delta PLC, it is crucial to first understand the concept of Programmable Logic Controllers. PLCs are essentially computers that are used to control industrial processes and machinery efficiently, ensuring seamless workflow. Delta PLC’s development over time reflects its commitment to technological advancements and its ability to adapt to the ever-changing demands of the industry.

Some of the series of Delta PLC include:

+S Series: 24VDC

+ES2 Series: 220VAC

+ES3 Series

+EC3 series

+DVP-ES3/2 Series Expansion Module

+PLC AS Series

+AS Series Motion CPU

These series of Delta PLC offer a range of features and capabilities, catering to various industrial automation needs.

What is ladder logic in PLC programming?

Ladder logic is a type of programming language that is represented through a graphical diagram, similar to a circuit diagram of relay logic. This programming language consists of two vertical lines called ‘rails’ and horizontal lines called ‘rungs’, giving it the appearance of a ladder. The primary languages used for programming a Programmable Logic Controller (PLC) are Ladder Logic and C. But Ladder Logic is often used as programming language for PLCs. The graphical representation of an Ladder Logic program is known as an Ladder Logic diagram (LLD). Ladder logic diagrams are graphical programming languages that execute through real-time input. They have two vertical lines, referred to as rails, with the left rail supplying power to the circuit. Each rung contains switches and output coils. Switches can perform OR, AND, and NOT operations, allowing for the creation of various programming logics in PLCs. A Ladder Logic diagram operates from left to right and top to bottom. When all the conditions of a rung are met, the connected output coil gets energized, activating the real-world system, such as turning on a motor or turning off a motor.

What is Siemens logo PLC?

Siemens LOGO PLC is a small computer system that helps control things in simple automation projects. The system can be programmed using LOGO Soft Comfort, which offers a graphical interface for creating and editing programs. To generate a new circuit program, users must pick out and place blocks within the program to design the logic functions for the system. Shortcut menus for editing objects provide a more efficient way to apply changes to the program. Configuring blocks enables customizing program to fulfill certain system requirements. It is necessary to establish connections or links between blocks for the program to function properly. It is also essential to understand the block connection indications that can assist to eliminate errors and make sure smooth operation. Mastering these skills is useful for the expert and effectual programming of Siemens LOGO PLC.

References:

https://basicplc.com/different-types-of-plc

https://www.linkedin.com/pulse/delta-plc-programmable-logic-controller-tgqkc