Download WPLSoft V2.48-Delta PLC Programming Software Free Google Drive

Delta WPLSoft V2.48 is Delta PLC programming software for DVP series PLCs. WPLSoft is the programming software for Delta’s PLC, which works alongside ISPSoft. This PLC programming software Delta is developed by Delta Electronics. It is important to note that PLC Delta is different from other PLC companies. Because copyright software, WPLSoft V2.48 of PLC Delta is provided for free of charge, which gives customers better economic prospects and creates economic benefits for users. In this blog article, we plchmiservo.com would like to discuss the Download WPLSoft V2.48 Delta PLC Programming Software with you, also Features of WPLSoft V2.48 Software, Delta Analog input module programming & Analog output programming by using the WPLSoft V2.48 Software and Some simple PLC Delta Programming Examples.

+WPLSoft Latest version V2.52 Free Download

Features of WPLSoft V2.48 delta PLC programming software

+WPLSoft V2.48 software is the recent version used to specialize in programming DVP-Series.

+The software is also used to create a program for active Delta PLC.

+WPLSoft Software is more compact than other Delta PLC Programming Software.

+The software is only 80 MB.

+The software is easily accessible and still fully supports DVP series programming commands.

+The software is used for those users who are new to PLC Delta Programming, recommended for 10,000 Step or less programs.

+WPLSoft V2.48 Software is supported for the following Operating Systems:

1. Windows XP (32-bit/64-bit)

2. Windows Vista (32-bit/64-bit)

3. Windows 7 (32-bit/64-bit)

4. Windows 8 (64-bit)

5. Windows 10 (64-bit)

Supported MODELS of delta plc programming software WPLSoft V2.48

The programming software WPLSoft V2.48 has the capability to support a range of PLC models, such as DVP ES, DVP EC, DVP EC3, DVP EX, DVP SS, DVP SA, DVP SC, DVP SX, DVP EH, DVP SV, DVP EH2, DVP EH2 L, DVP SE, DVP ES2, DVP SX2, DVP SA2, DVP EX2, DVP SS2, DVP SV2, DVP EH3 L, DVP EH3, DVP MC. In addition, the software is also compatible with PLCs integrated into VFD-E, VFD-C2000, VFD-CH2000, VFD-CT2000, VFD-C200, VFD-CP2000 and PLC integrated display screens such as TP04P, TP70P-IO, TP70P-RM.

DVP PLC Application Examples of Programming

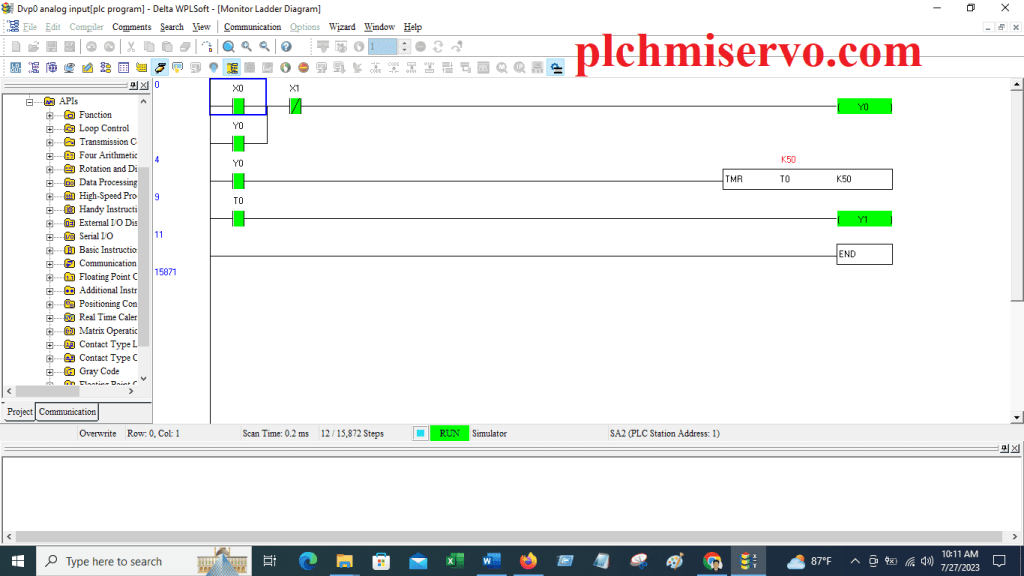

>SIMPLE PROGRAMMING

There are several ways by which a PLC can be programmed in order to perform a specific task, but one of the simplest of them is to use a ladder diagram. In its simplest form, it is a graphical programming language that originated from electrical relay circuits.

> Delta plc counter programming examples & Delta plc timer examples

Timers and counters are basic components of PLC programming, particularly for ladder logic programming. They permit you to control the timing and counting of facts, such as turning on or off gadgets, activating alarms, or executing subroutines.

The timer value in Delta PLC

delta plc timer example-TIMER: There are mainly two categories of timer- 1. Retentive and 2. Non retentive. Within these two categories, timers can be further classified as on-delay or off-delay. The timer base is set at 10ms. For a 10-second interval, the timer would be set to 10*10= 100ms or 10 seconds. An example of an on-delay timer would be one used on a conveyor’s start button. This timer would require the start button to be held for 5 seconds before the conveyor begins moving. Another on-delay timer could be used to activate a warning horn and light when the conveyor starts.

delta plc counter programming: PLC (programmable logic controller) instructions that are responsible for increasing or decreasing an integer number value when there is a transition from a “false” (0) to “true” (1) bit are called counters. There are three main types of counters which are up counters, down counters, and up/down counters. Up counters increment the integer value while down counters decrement the integer value. On the other hand, up/down counters can increment and decrementing the integer value based on the input signal. These counters are an essential tool in the field of automation as they help keep track of the production and ensure efficient control of industrial processes. They can also be programmed to reset automatically after reaching a specific value, providing maximum efficiency and accuracy in manufacturing processes.

>Delta Temperature Program PT & TC

This program allows you to calculate the difference of temperature between two points using PT (Platinum Resistance Thermometer) and TC (Thermocouple) sensors. You can simply enter the values of the PT sensor and TC sensor in the provided fields and click on the “Calculate” button. The program will then display the temperature difference between the two sensors.

> delta analog input module programming

The Delta PLC Programming systems employ delta analogue inputs in order to monitor and control the inputs of various types of sensors used in industrial factories. These sensors can detect a change in voltage, current or resistance in response to changes in the environment or other system measurements. This is especially useful for input devices or real-world analog inputs like weighing scales, oil pressure sensors, and temperature sensors. To fully automate factories, it is important to have a thorough understanding of the different types of PLC inputs that can be utilized.

This is essential in creating an efficient control system that can improve the overall production and performance of the factory. Proper knowledge and application of these PLC inputs can reduce errors, ensure accuracy and safety, and boost productivity in industrial factories. It is imperative that automation engineers keep themselves updated with the latest technologies and methods that can optimize and streamline these industrial processes. By effectively implementing these PLC inputs in control systems, it is possible to significantly improve factory output and maximize efficiency.

>Delta Analog Output Programming

In Delta PLCs, there are two main types of analog output signals available – voltage and current signals. A PLC analog output has the option to be either a voltage or current analog output. PLC analog outputs are commonly used to regulate the performance of important equipment such as actuators, valves, and motors in industrial settings. The standard ranges of analog outputs that can be accessed via programmable logic control (PLC) systems are 5 V, 10 V, 0-10 V, 4-20 mA, and 20 mA.

A noteworthy example of analog output is the one generated by the DCS to converters. This is because whenever there is a requirement to send a signal for current to a pneumatic converter that exists in the field located within a hazardous area, the use of a grounded barrier is strongly recommended. This will help in the efficient transmission of the required signal. Thus, it can be seen that the correct functioning of analog outputs is a critical aspect of industrial environments, which necessitates the use of appropriate methods to guarantee proper and secure functioning.

DVP 12SE software & DVP12SA2 software

The DVP 12SE & DVP12SA2 is the delta Programmable logic controller (PLC), the delta DVP 12SE & DVP12SA2 PLC has 8 Digital Input and 4 Digital outputs, The DVP 12SE PLC has USB and Ethernet port for the communication of Delta PLC to PC, also has RS485 Port for the MODBUS Communication. Also, we can easily communication between the HMI to PLC By using the ethernet port & RS485 Port. The 12sa2 plc has RS232 Port and RS485 Communication function port. The Delta DVP 12SE software & DVP12SA2 software programmable logic controller (PLC) programming WPL Soft and ISPsoft, The WPLSoft is the programming software of delta all DVP Series programmable logic controller (PLC), but if you want to work the AS, AH series PLC, then you have use the ISPSoft Programming Software. The DVP 12SE PLC Programming cable Mini USB and Ethernet, & The DVP12SA2 PLC Programming cable RS232 ACAB230.

Download WPLSoft Delta PLC Programming Software

We have given the google drive link Download WPLSoft V2.48 Delta PLC Programming Software, so click on the link to download the delta plc software for windows 10.

Extract Password: plchmiservo.com

+ DVP PLC Application Examples of Programming Manual pdf

Thanks Guys, if need any help during the programming & Program Upload and download, or need any delta plc, HMI, Servo, & VFD, then you can contact us via email or WhatsApp.

+delta WPL Software free download WPLSOFT V2.51 Latest version

+ delta plc ISP Software free download ISPSOFT V3.17 Latest version

+Delta Ethernet Module communication software EIP Builder free download