[Download] Delta Software Delta Electronics CNCSoft B Series & CNCSoft A

CNC, short form for Computer Numerical Control, refers to the use of software to make procedures and program codes that govern the movements of various tools and machinery in a factory setting. The CNC Soft has been two types CNCSoft B & CNCSoft A. This technology is widely utilized in controlling a diverse range of machinery such as routers, lathes, grinders, and mills. By doing so, CNC software surpasses the limitations of traditional manual machining in terms of precision, production rate, and speed. In fact, CNC software greatly facilitates the production of intricate and complex parts made from metal and plastic, which would otherwise be extremely challenging to create manually. So, how exactly does CNC software function? It all begins with computer-aided design (CAD) software, which generates a two-dimensional (2D) drawing or a three-dimensional (3D) solid model of the desired part. The design is thereafter brought into CAM or <Computer-Aided Manufacturing> software. The CAM software takes the design and generates tool paths, which can be understood as a series of coordinates that dictate the path the cutting tool will follow. These tool paths are subsequently converted into a set of simple programming language instructions. The most common programming language used is G-code or ISO code, as it allows for precise control over the manufacturing equipment. The CNC software interprets the G-code and initiates a series of numbered and sequential instructions for the CNC machine to execute, ultimately machining the desired part with great accuracy and efficiency. However, today we (http://plchmiservo.com) want to discuss the [Download] Delta Electronics CNCSoft, Features of Delta Electronics CNCSoft, Application of Delta Electronics CNCSoft & CNC Accessories, and also How to download Delta Electronics CNCSoft Software from Delta Electronics.

+delta dop hmi software download

Features of CNC Soft Delta Software

+Compared to manual machining, CNC software offers numerous features. Firstly, it significantly increases the capabilities of CNC machines, allowing for more complex and intricate designs. It enhances production rates, ensuring higher output and faster turnaround times.

+The reliability of CNC software surpasses that of manual machining, as it eliminates human error and provides consistent results. With its high-speed, high precision capabilities and superior surface finishing, it ensures faster, higher quality, and more stable machining processes. This makes it highly suitable for industries such as high-speed tapping, engraving, milling, mold machine manufacturing, and component processing.

+CNC software enables uniform product quality, ensuring that each piece meets the same high standards.

+CNC software offers increased versatility, as it can handle a wide range of machining processes and materials. It also enhances safety by minimizing the need for manual intervention, reducing the risk of accidents.

+The use of CNC software also leads to fewer labor hours required, as it automates many tasks that would otherwise be done manually. This not only cuts down on time but also lowers expenses for labor.

+CNC software can also transform a regular PC (personal computer) into a powerful CNC controller. For instance, the UCCNC Control Software is a comprehensive motion control software that supports full G-code and production specifications. When used with the UC100 USB Motion Controller, which provides fast and reliable communication through the standard USB interface, any Windows-based PC can effectively function as a CNC controller.

+The UCCNC Control Software allows operators to work in Manual Data Input (MDI) mode, enabling them to input machining commands individually or utilize existing G-code CNC programs.

+CNC software requires lower maintenance compared to manual machines, as it eliminates the need for regular manual adjustments and repairs. This leads to decreased interruption and enhanced productiveness.

+CNC software contributes to cost savings by optimizing material usage and reducing waste. It also eliminates the need for specialized tools, as CNC machines can perform multiple operations with a single setup.

Application of Delta Electronics CNCSoft & CNC Accessories

The Delta Electronics CNC controllers are equipped with Delta’s DMCNET motion bus, which enables them to achieve highly precise, high-speed, and smooth processing. This is made possible through the integration of the induction motors (IM), PM (permanent magnet) motors, AC Servo System ASDA-A3 Series/ ASDA-B3 Series towards the encoders, and spindle. The CNC controllers are designed to accommodate the standard ISO G-code structure and utilize algorithms that ensure performing accurately and speedily. In addition, these controllers have a built-in human machine interface (HMI) that allows for the customization options for different industries and development of a easily operated interface. Delta Electronics offers a range of CNCSoft and CNC Accessories that have various applications in different industries. Delta Electronics’ CNCSoft and CNC Accessories offer versatile solutions for industries in need of precise and high-speed performance. With their advanced features and customization options, these products can greatly enhance the efficiency and competitiveness of businesses in various markets. Delta’s product list includes the CNC B Series, which comprises the CNC Solution B Series and the OPENCNC Controller NC EB Series. These products have been created to cater to the distinct needs of various industries. The comprehensive range of CNC accessories of Delta enhance the functionality of their controllers. These accessories include a big touch screen for specifying a desired and user-friendly interface and running the OpenCNC controller. Other accessories supported by Delta include a second operating panel, touchscreen, expansion I/O, and handwheel.

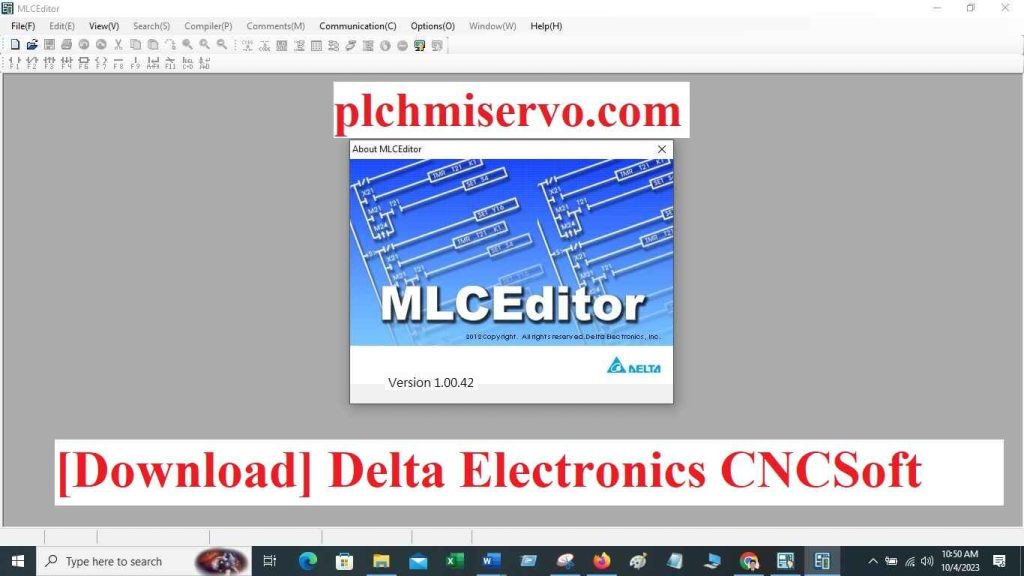

How to download CNCSoft B & CNCSoft A Series Software from Delta Electronics?

+To download the CNCSoft Software from Delta Electronics, visit the google.com on your chosen browser. Then type CNCSoft Delta Software & Go to Delta Download Center website.

+After that, go to the download center of Delta Electronics website- (https://downloadcenter.deltaww.com/en-US/DownloadCenter)

+Choose the “Select Product” section & type “CNCSoft” or “CNCSoft Software” in the search bar under this section. Or directly click on the below link- https://downloadcenter.deltaww.com/en-US/DownloadCenter?v=1&q=CNCSoft&sort_expr=cdate&sort_dir=DESC

+After searching the Delta Electronics CNCSoft, it is recommended to click on the download link of the appropriate version of CNCSoft Software.

+<<<Alternative method for downloading CNCSoft is “Google drive link” instead of Delta website. Just visit the (http://plchmiservo.com) website to access the Google drive download link of Delta Electronics CNCSoft Software.

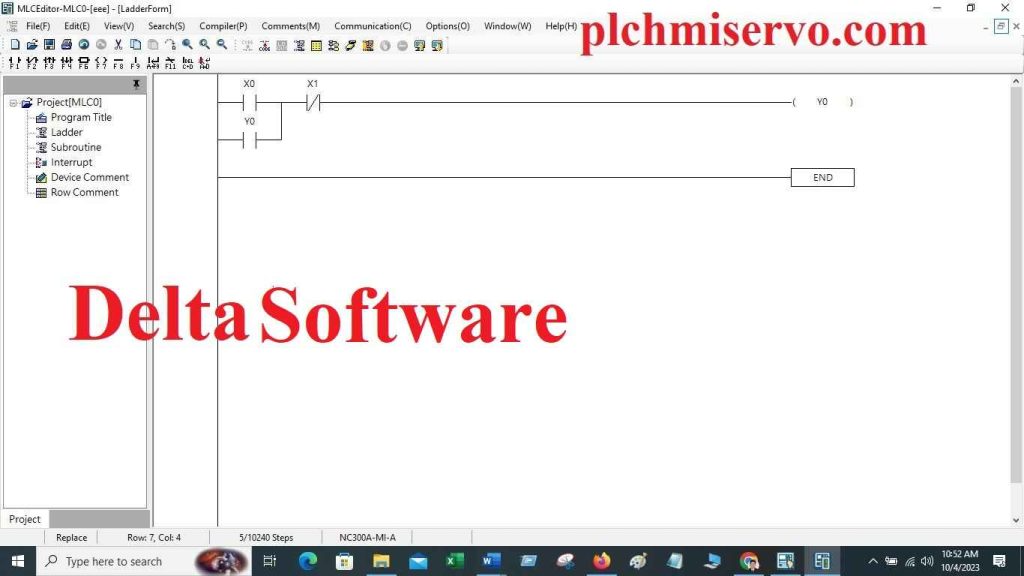

+CNCSoft B Delta CNC Controller Software

+CNCSoft A Delta Software for CNC

Conclusion

If any of the information provided has been useful to you, please do not hesitate to share it with your friends, relatives and colleagues. This will allow them to individually experience the outstanding features and benefits of the Delta Electronics CNCSoft Software. We sincerely appreciate the time you have taken to read through this content, and we look forward to connecting with you once again in the near future.

![[Download] Delta Electronics CNCSoft](https://plchmiservo.com/wp-content/uploads/2023/10/logo.jpg)

![[Download] FPWin Pro 7 Full Version Download](https://plchmiservo.com/wp-content/uploads/2023/09/Download-FPWin-Pro-7-Full-Version-Download-150x150.png)