[Download] S7 200 Smart PLC Software Download-MicroWIN Smart V2.6 Free 100% Real

Step7 Microwin Smart V2.6 is the latest specialized programming, configuring, and operating software for the S7200 Smart Programmable Logic Controller (PLCs) manufactured by Siemens. Step 7 Micro/WIN SMART is a user-friendly software designed for small and medium projects. it supports the Ladder diagram (LD), Function Block Diagram (FBD), and Statement List (STL) programming languages also and allows for easy configuration and parameterization of SMART PLCs. Siemens S7200 Smart PLC is used in various sectors, also S7200 PLC has many powerful functions, compact in size, low cost, and high protection system. For high protection, users have chosen the smart PLC, and till now this PLC could not crack the password. Siemens S7200 Smart PLC Has an ethernet port, and COM Port, so users can easily program upload and download by the ethernet cable and PPI Cable. However, today we are going to show the S7 200 Smart PLC Software Download-MicroWIN Smart V2.6 latest software, also How to download the Step7 MicroWIN Smart latest software and install it, and how to programming and program upload and download by using the S7 200 SMART PLC Software MicroWIN Smart.

+Click here and download Siemens S7200 Smart Latest version software MicroWIN Smart V2.7

Some New Functions of Siemens S7200 Smart PLC Software V2.6 Newer version

+ Only See the following CPU models support the Siemens S7200 SMART PLC software V2.6 firmware

+The newer models of Smart s7 200 PLC con not be downgrade to V2.4, V2.5 or any previous version.

+Any previous S7200 Smart PLC Relay type SR or Transistor type ST model with an article number ending with 0AA0 cannot be upgraded to Version 2.6.

+Step 7 MicroWIN Smart Software V2.6 and S7 200 Smart PLC of V2.6 Added Web server function as below included

+Web Server Wizard: The web server Wizard is used to configure & create the web server functions.

+Certificate Management Wizard: The certificate Management Wizard is used to Manage, Upload & Download certificates for the web server.

+Through browsers, Web pages provide the function to modify the PLC data and view the PLC Data.

Some of the key features of Step 7 Micro/WIN SMART include:

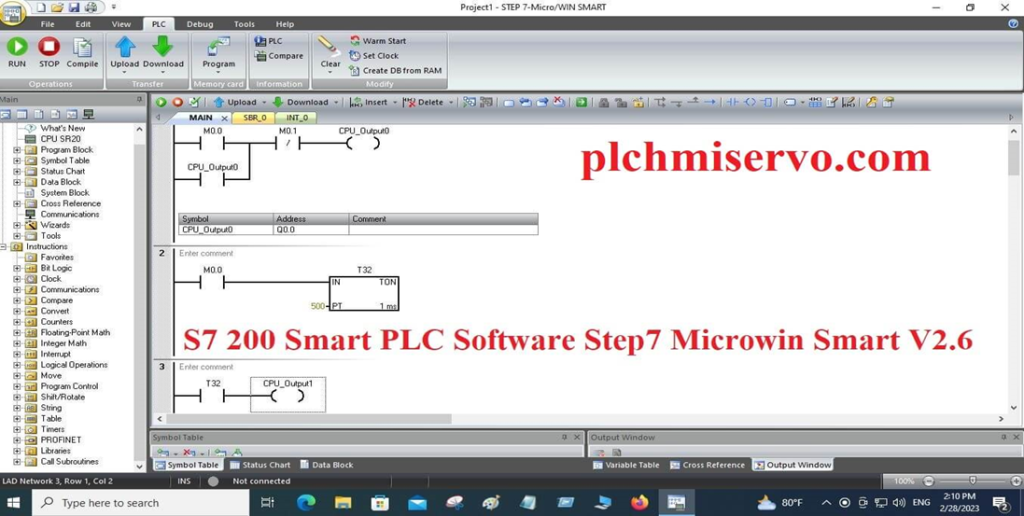

+MicroWIN Software Support for multiple programming languages such as Ladder Diagram & Statement List and Function Block Diagram (LAD and STL, FBD), We have created the program Ladder Diagram see the below figure

+User friendly interface with drag-and-drop functionality

+Quick configuration and parameterization of SMART PLCs

+ MicroWIN Smart Software does not Support offline simulation and testing, if you want to check the program then you have to connect the live S7200 Smart PLC. otherwise, you cannot check the program.

+This software has Built-in diagnostics and troubleshooting tools functions

+Integration with other Siemens automation tools

Application of Siemens S7200 Smart PLC

Siemens S7200 SMART PLC is designed to provide reliable and cost-effective solutions for controlling a wide range of automation tasks, including process control, motion control, and data acquisition.

Some common applications of siemens S7200 Smart PLC

+Process control: The Siemens S7 200 Smart PLC can be used to control various processes in manufacturing, such as pressure control, temperature control, flow control, and level control.

+Motion control: S7 200 Smart PLC can be used to control motors & drives, also other moving parts in manufacturing equipment, such as robotics, assembly lines, and conveyor systems.

+Building Automation: S7200 SMART Programmable Logic Controller (PLC) can be used to control the HVAC Systems, Building automation systems,s and lighting automation systems.

+Data Acquisition: The siemens MicroWIN SMART PLC can be used to collect data from various types of sensors, such as pressure sensors, temperature sensors,s and flow meters.

Overall, the siemens s7200 SMART PLC is very reliable and gives a versatile solution for a wide range of industrial applications.

Supported Operating System and PC Requirements for the MicroWIN Smart Software

+Microsoft WIN 7/32bit & 64 bit, Needs to RAM Minimum of 2GB, But Recommended 4GB or above, the processor needs a minimum of 2 GHz or Above

+Microsoft WIN 10/32bit & 64 bit, Need to RAM 4GB Minimum, But Recommended 8GB or above, the processor needs to be 2 GHz minimum or More

+Hard Disk Space will need to Free 350MB.

+ Screen Resolution 1024*768, Keyboard, and windows Supported Mouse.

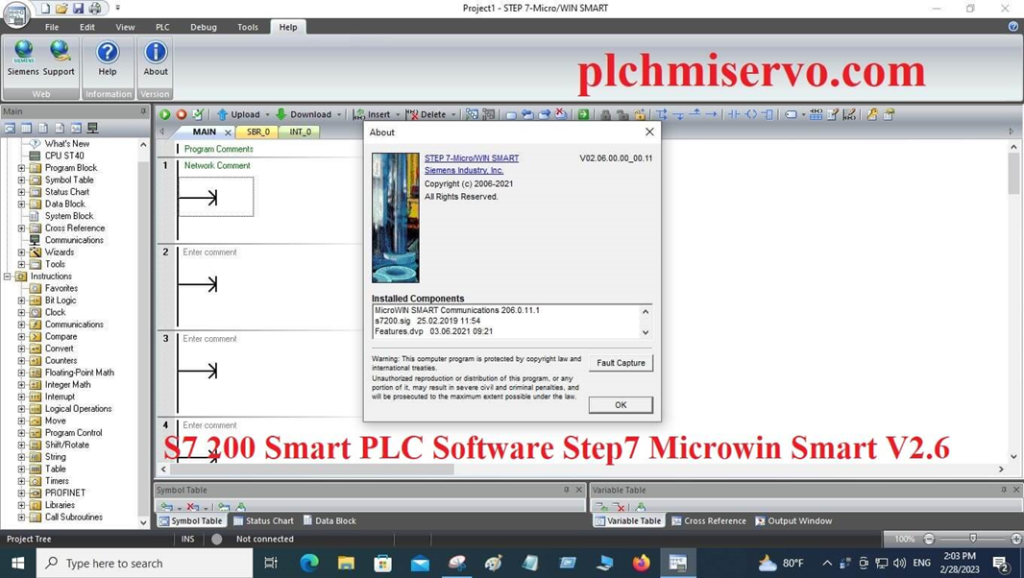

We have installed the S7 200 SMART PLC Software MicroWIN SMART V2.6 Microsoft Windows 10/64 bit without any problems.

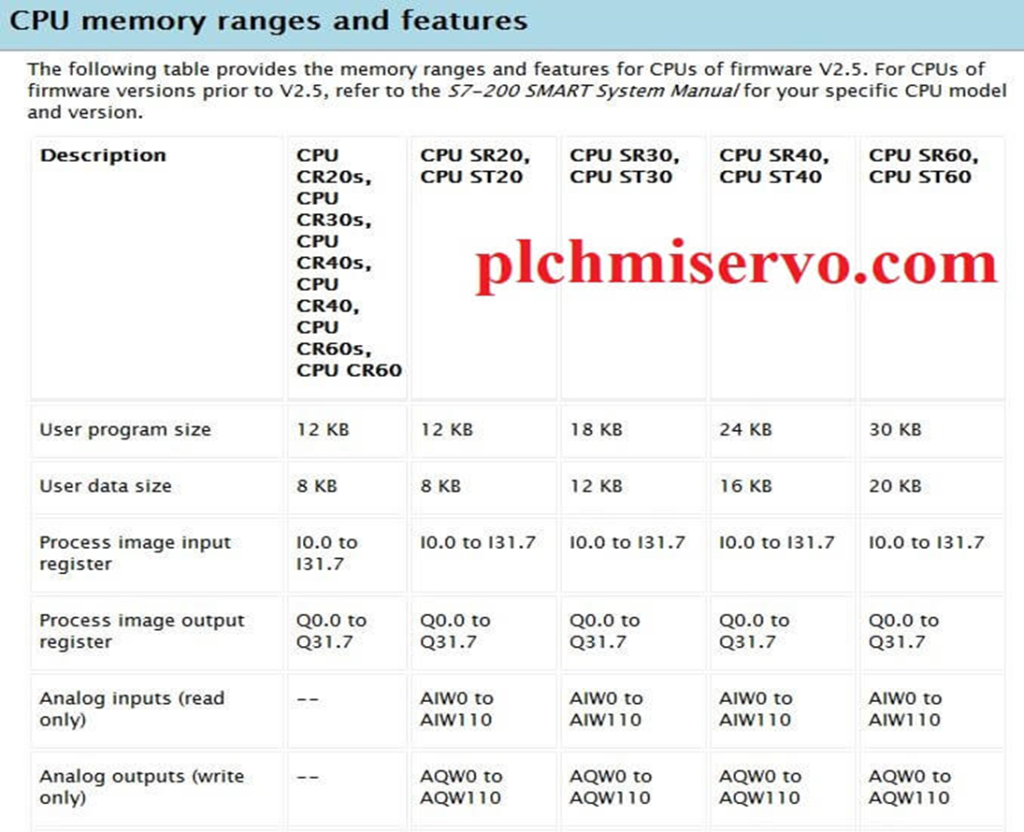

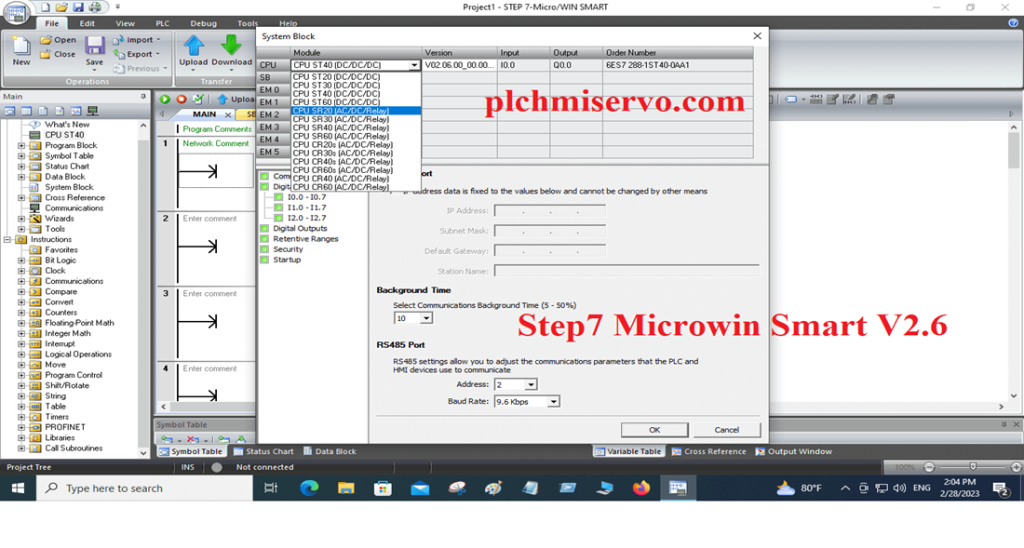

Supported Model of the MicroWIN SMART V2.6 Software

S7 200 SMART Software MicroWIN SMART V2.6 supports the following models

+CPU ST20 (DC/DC/DC), CPU ST30 (DC/DC/DC), CPU ST40 (DC/DC/DC), CPU ST60 (DC/DC/DC),

+CPU SR20 (AC/DC/Relay), CPU SR30/CPU SR40 (AC/DC/Relay) and CPU SR60 (AC/DC/Relay)

+ CPU CR20S (AC/DC/Relay), CPU CR30S (AC/DC/Relay), CPU CR40S (AC/DC/Relay), CPU CR620S (AC/DC/Relay), CPU CR40 (AC/DC/Relay), CPU CR60 (AC/DC/Relay)

Setup Process of MicroWIN SMART V2.6

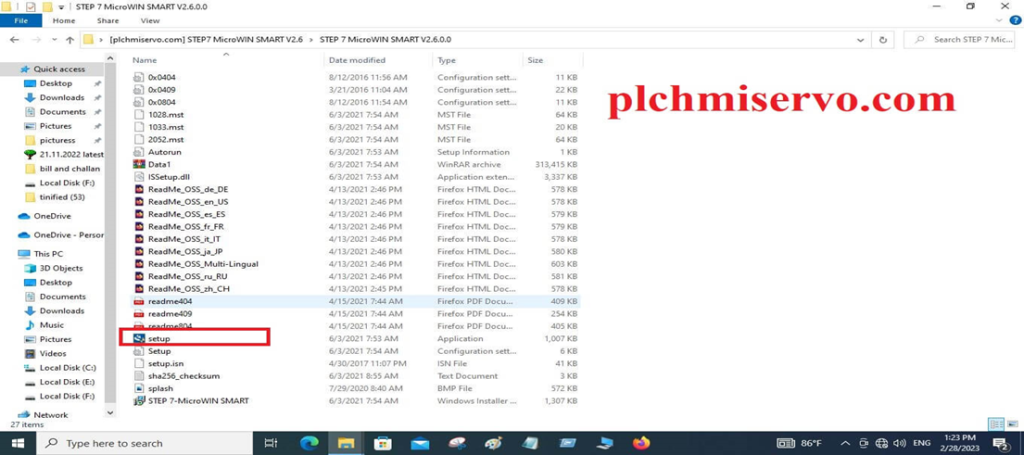

First of all, Download the S7200 SMART PLC Software MicroWIN Smart V2.6 from our website or Siemens’s Official website, then unzip the software

+Step 01: After unzipping the MicroWIN Smart V2.6 software Then Double Click on Setup and click on Yes.

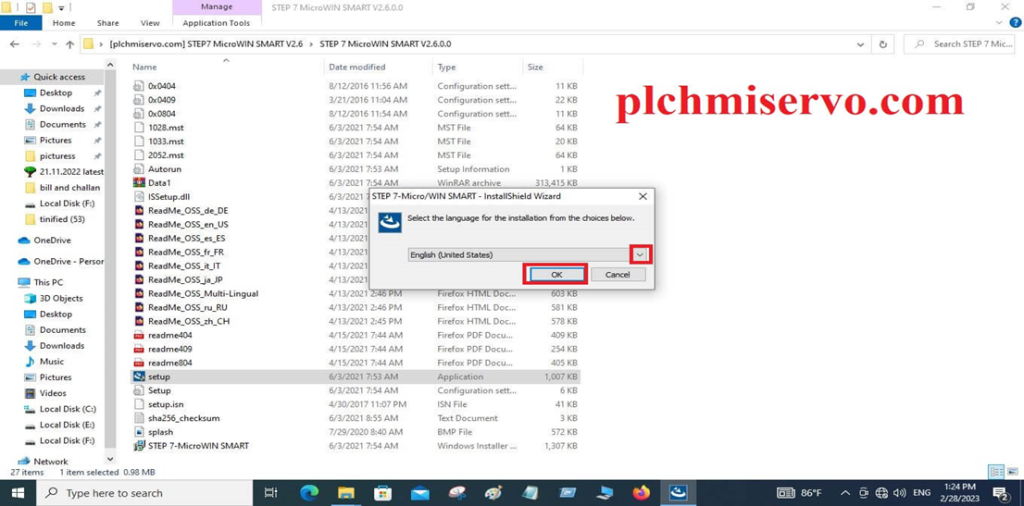

+Step 02: Then choose the installation language, we have selected English (United State) then click on ok.

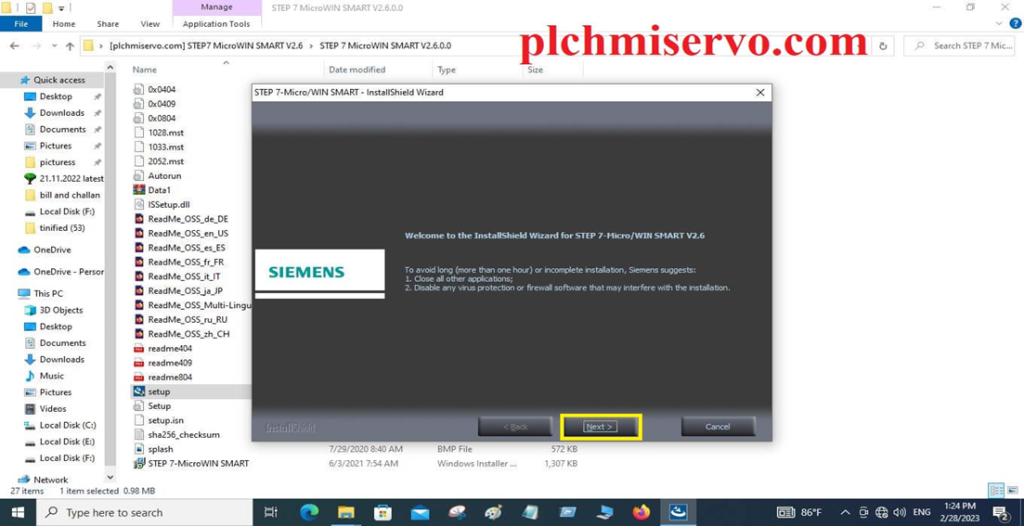

+Step 03: Then Welcome to the Installation Wizard Step 7 MicroWIN SMART V2.6 Window show, then click on Next

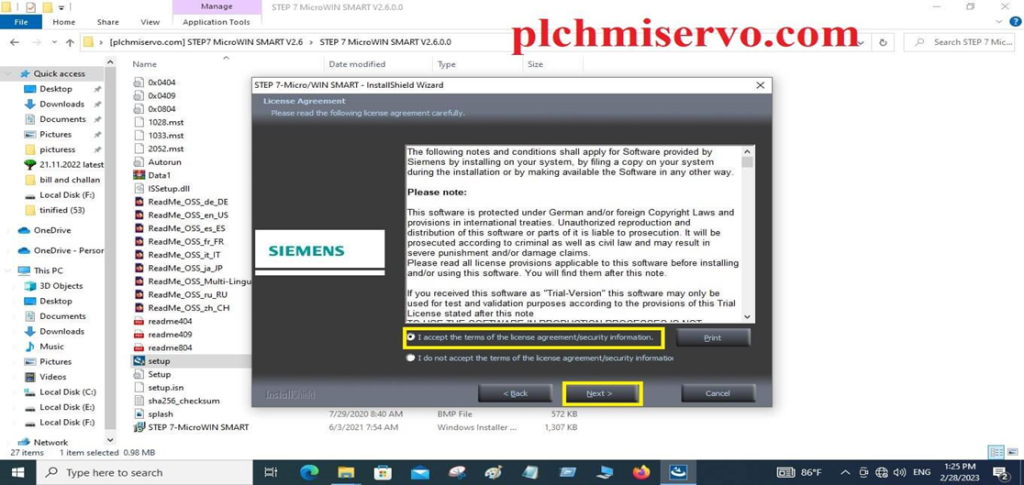

+Step 04: Then the License agreement window shows, so click on I accept the terms of the license agreement & click on Next.

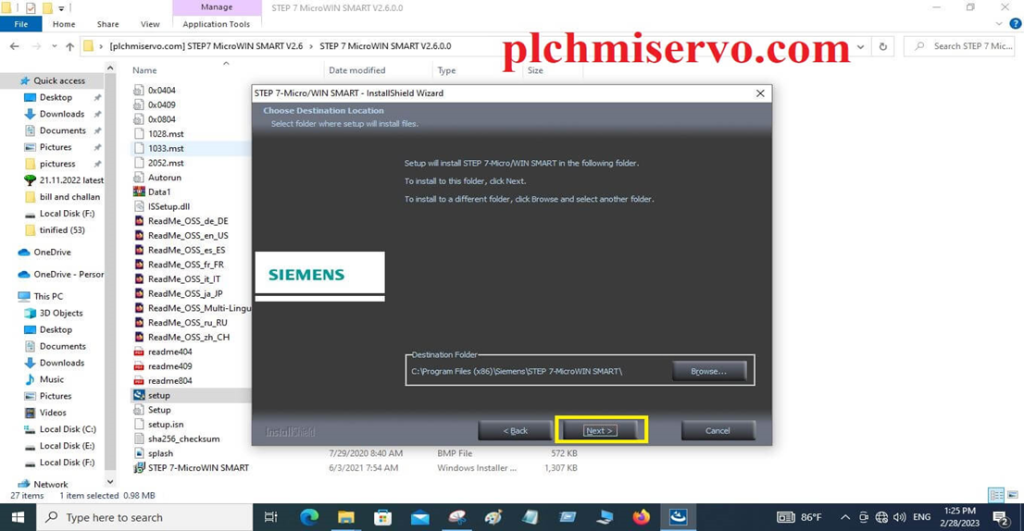

+Step 05: Then choose the “installation location” of software S7 200 MicroWIN Smart V2.6 and click on Next and wait for installation.

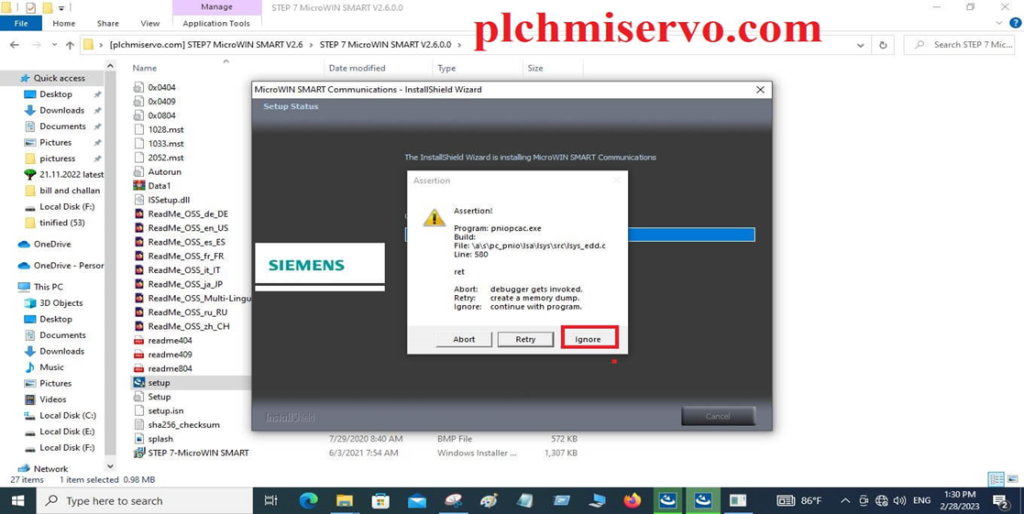

+Step 06: During the software installation, this will show this Window, so Click on Ignore

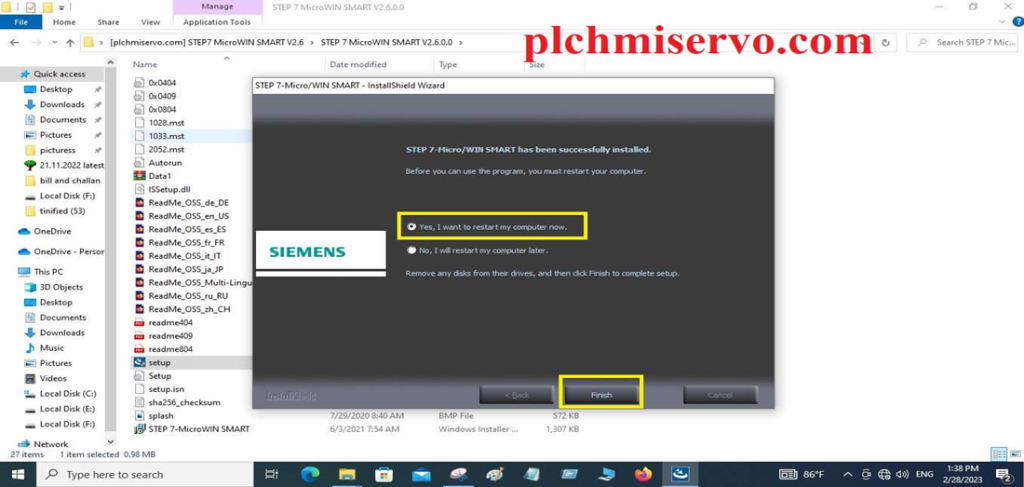

+Step 7: When successfully installed the Step 7 MicroWIN Smart software then your PC will be restarted, so click on Finish, and wait for the again PC Starting.

How to File Upload Program & Download Program by using Step7 MicroWIN Smart v2 6

Download Program:

After creating the program, then connect the programming cable PPI Cable or Ethernet Cable.

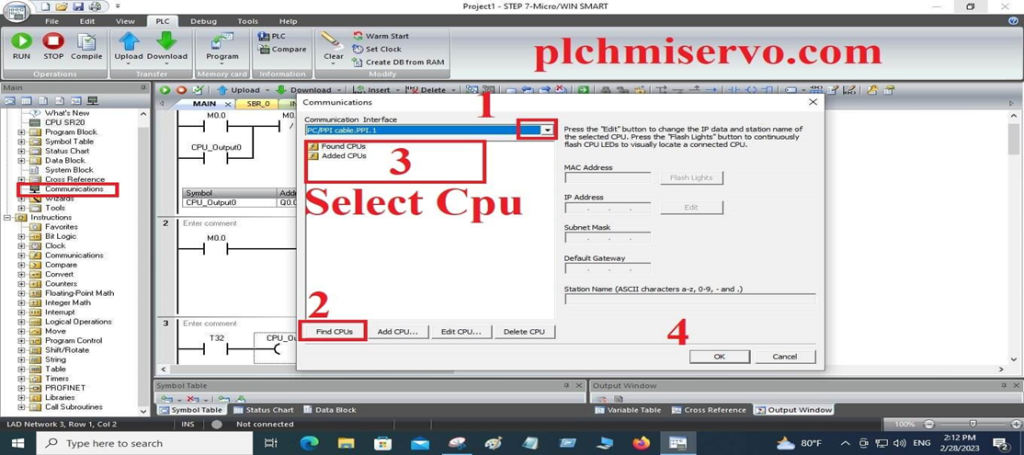

+Then Go to Communication (For PPI Cable) then select PC/PPI Cable.PPI.1, then click on find CPU, When CPU Found then select the CPU and Click on OK.

+For Ethernet Cable, Go to Communication then select Realtek PCIe GbE Family controller.TCPIP.1, When find the IP Address then will show the Right side of the software MicroWIN smart IP Address, MAC Address, and Subnet mask, then set the IP for Your computer, so go to the Open network & internet setting, then click on Ethernet, then click on Change adapter setting, then write button click on ethernet and Click on properties and click on Internet protocol v4 (TCP/IP v4), then click on properties then click on Use the following IP Address, then set IP Address, Subnet mask then click on OK.

+When successfully setting up the IP address and Subnet mask then Go to download and click ON It and wait for downloading the program.

+Then go to the Online and Click on “Download Program & Data”, then will download the program.

Upload:

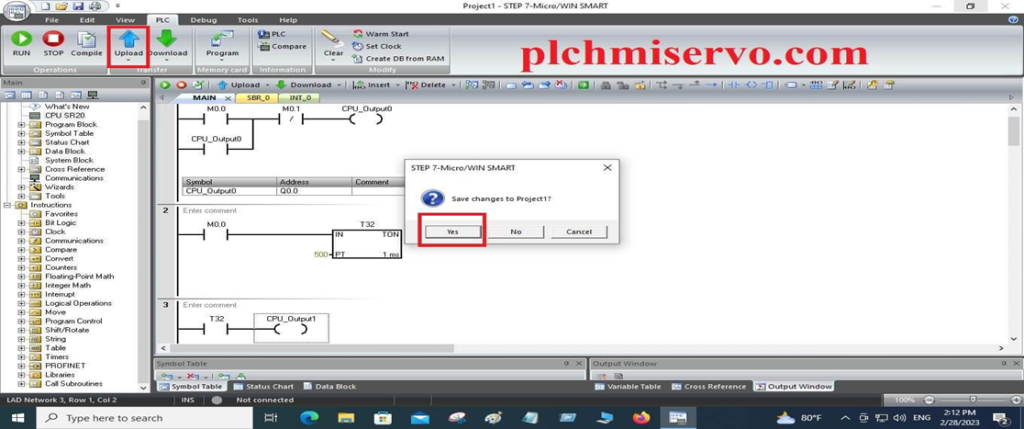

+After choosing the Programming cable (Ethernet & PPI Cable (Pint to point Interface) then Go to the MicroWIN Smart V2.6 Software and Open it, after opening the MicroWIN Software.

+Then Go to Upload Then save the project location and chose the cable type, which we have described above, then wait for the Uploading the program.

>>>> S7 200 Smart PLC Software Download-MicroWIN Smart V2.6 Google Drive Link

We have given the S7 200 Smart PLC Software Download-MicroWIN Smart V2.6 software (Google Drive) Link, so click on the below link to download your required software.

+ Download Link: Step7 MicroWIN Smart PLC Software Latest version V2.6 Google Drive

+ Unzip Password: [plchmiservo.com]

+ MicroWIN Smart PLC Software User Manual PDF

Thanks! If you need any help during the MicroWIN SMART V2.6 S7200 PLC Software setup or programming, also if you need any project support or Program Upload /Download, or need any troubleshooting of the S7200 PLC or Program, then you can contact us Via email at plchmiserv02@gmail.com or WhatsApp Number at+8801911300632.