What is induction motor & What is synchronous motor & Difference between stepper motor and servo motor

Hi dear guys, plchmiservo.com will be describe What is synchronous motor and induction motor, also difference between stepper & servo motor.so for details please see the details given below.

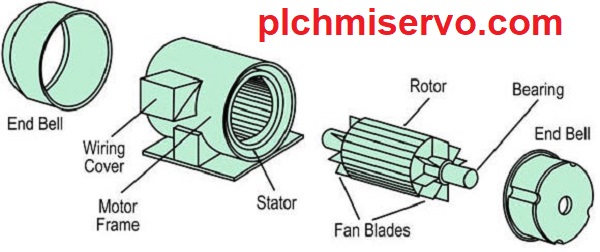

What is induction motor, An induction motor is an AC electric motor that operates on alternating current to convert electrical energy into mechanical energy. It gets its name from the fact that the electric current needed to generate torque in the rotor circuit is produced through electromagnetic induction from the rotating magnetic field created by the stator winding. These motors are known as asynchronous because the rotor spins at a speed slightly lower than the speed of the rotating magnetic field. The induction motor works by converting electrical energy into rotational energy through the interaction of the stator and rotor components. The stator is connected to an AC power supply, while the rotor receives its power through electromagnetic induction from the stator.

What are the types of induction motor & What is synchronous motor and induction motor

Induction motors are classified into two main categories based on the power supply they are fed with: single-phase induction motors and three-phase induction motors.

+Single-Phase Induction Motors

These motors are connected to a 1-phase AC power supply. They are not self-starting and require separate starting circuitry to provide a rotating field to the motor. The direction in which the rotor of a single-phase motor turns is determined by the starting circuit, as the normal running windings allow for movement in either direction. There are four subcategories of single-phase induction motors:

1. Split Phase Induction Motor: This type has a low starting current and moderate starting torque.

2. Capacitor Start Induction Motor: This type uses a capacitor to create a phase shift between the two windings, allowing the motor to start.

3. Capacitor Start and Capacitor Run Induction Motor: This type keeps the capacitor connected even after the motor has started, improving the motor’s efficiency and torque.

4. Shaded Pole Induction Motor: This type uses a copper wire turn around part of a pole to create a delayed magnetic field, imparting sufficient rotational field energy to start the motor.

+Three-Phase Induction Motors

These motors are connected to a 3-phase AC power supply. They are self-starting due to the internal phase differences between the three single-phase lines, which create a rotating magnetic field that induces a current in the rotor, causing it to turn. There are two subcategories of three-phase induction motors:

1. Squirrel Cage Induction Motor: This type has a simple rotor construction with bars made of aluminum, brass, or copper. It is commonly utilized as industrial drives due to their self-starting capability, reliability, and cost-effectiveness.

2. Slip Ring or Wound Rotor Induction Motor: This type has a rotor winding that is connected to the slip-rings. It is recognized for its strong initial rotational force.

What is synchronous motor

What is synchronous motor, A synchronous electric motor is an alternating current (AC) motor where the shaft rotation is in sync with the frequency of the power supply. This means that the rotation period matches an exact number of AC cycles. These motors use electromagnets on the stator to create a magnetic field that rotates at the same speed as the current. The rotor, which can have permanent magnets or electromagnets, turns in sync with the stator field to create a second rotating magnetic field. If a synchronous motor has independently excited multiphase AC electromagnets on both the rotor and stator, it is referred to as doubly fed.

What is single phase ac motor

A single-phase AC motor is an electrical motor that converts single-phase electrical energy into mechanical energy using magnetic interactions. These motors are commonly used in homes, businesses, and some industries due to their cost-effectiveness and simplicity. To make single-phase motors self-starting, techniques like split-phase and capacitor methods are employed. These motors are used in various appliances like fans, washing machines, and pumps due to their reliability and ease of maintenance.

What is a 3 phase motor?

A 3-phase motor is an electrical motor that is commonly powered by a three-phase system, which consists of three separate currents. This power can be obtained from either a three-phase mains supply or a frequency inverter. These motors come in two main types: synchronous and asynchronous motors.

Difference between stepper motor and servo motor

+A stepper motor operates using an open-loop control system, meaning it does not receive feedback on its position, while a servo motor uses a closed-loop control system with real-time feedback to maintain precise positioning.

+Stepper motors are generally more suitable for applications that require lower cost, simple control, and where positional accuracy is less critical. On the other hand, servo motors are ideal for applications demanding high precision, dynamic response, and continuous feedback.

+Stepper motors exhibit relatively constant torque output at low to medium speeds, making them suitable for precise positioning and low-speed operation. But, servo motors can deliver higher speeds and torque outputs compared to stepper motors, maintaining a relatively flat torque curve over a wide range of speeds for consistent performance at both low and high speeds.

+Servo motors tend to have more intricate designs compared to stepper motors, which are known for their simplicity in design.

+Stepper motors do not exhibit hunting in the same scenario, while servo motors experience this phenomenon during the stop position.

+Stepper motors are well-suited for applications with low rigidity. But servo motors are not recommended for use in low rigidity mechanisms, such as those utilizing a belt and pulley system.