what is an automation & kinds of automation

Automation refers to the use of programs, robotics, technology, or methodologies to achieve desired outputs with lowest human involvement. In today’s modern society, automation is widely prevalent and has a multitude of uses, including in enterprise applications like business process automation (BPA), AIOps, and enterprise, as well as in industrial applications such as robotic technology in automotive manufacturing and in consumer applications like home automation. Automation is essential for driving digital transformation. It is also instrumental in facilitating the growth and scalability of businesses. Automation technology and software are utilized across various industries, ranging from finance and healthcare to utilities and defense, and virtually everywhere in between. Businesses leverage automation to enhance productivity and profitability, enhance customer service and satisfaction, reduce costs and operational errors, comply with regulations, optimize operational efficiency, and more. Effectively leveraging automation can provide organizations with a significant competitive edge.

Type of Process

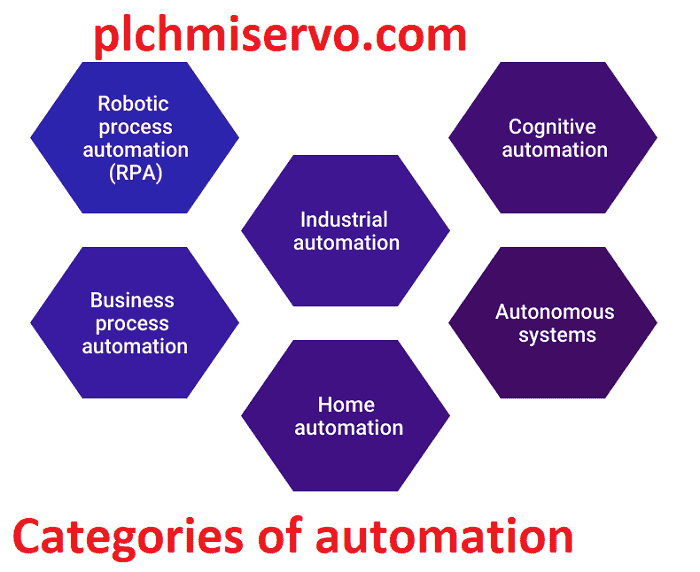

Categories of automation/kinds of automation

There are mainly 6 types:

1. Fixed : This type of process is designed for repeatedly carrying out the same set of tasks without changes. The manufacturing process configuration remains fixed, making it suitable for producing identical units through repetitive actions. For example, If the process of auto.. involves performing the same actions using the same components repeatedly, it can be classified as fixed automation.

2. Programmable : In this process, the equipment or robots are controlled through programming, allowing for batch production. The program can be modified to change the sequence or process as needed, enabling flexibility in production. This also enables implementing advanced process.

3. Flexible : An extension of programmable automation, flexible auto… allows for quick product or process changes with minimal downtime and manual intervention. This flexibility results in higher production rates.

4. Process : This type of process uses technology to automate manual procedures by integrating whole systems and data. It combines various auto… types into a connected system, managing business processes for transparency and workflow efficiency. Process auto.. is utilized more frequently in businesses where software programs or applications carry out a series of tasks within the contemporary digital organization.

5. Integrated : An integrated process system is a complete structure that uses computer control to automate all aspects of a manufacturing process. It streamlines communication between different automated processes, reducing complexity.

6. Robotic Process (RPA): RPA involves software robots that mimic, manage and perform human actions based on programmed rules. These robots can be created/built and deployed to automate tasks like data extraction from insurance forms or screens, product arrangement on shelves, and other rule-based activities.

Description of fixed automation and flexible automation

#Fixed automation

Machines and computers with programmed instructions control fixed automation systems, directing their actions, providing notifications, and tracking production metrics. Fixed automation is generally well-suited for producing large volumes of products. The series of tasks in fixed process is quite straightforward, involving basic motions like rotation or linear movement.

Advantages :

+High production output

+Low unit cost

+Consistent quality

+Automated material handling like AGVs

+Easy to trace production process

+Limited maintenance required

Disadvantages :

+High initial installation cost

+Inflexible, entire units must be replaced for new tasks

+Difficult to adapt to changes

Fixed is best applied in situations with:

+High steady demand for generic products requiring no changes

+Industries like automotive machining lines, some assembly, chemical processing

+Continuous flow production lines

An example is soft drink factories using dedicated fixed machines to produce vast quantities of identical beverages for high demand.

#Flexible automation

Flexible automation allows producing different product types without complex reprogramming by quickly switching between tasks. It builds on programmable automation with precise electromechanical controls like industrial robots and CNC machines.

Advantages of Flexible Auto..:

+No batching of identical products required

+Rapid changeovers between different product types

+No downtime for production changes

+Well-suited for batch production

+Allows for customization and varying demand

Disadvantages of Flexible Auto…:

+Higher unit cost

+Expensive customized automation machinery

Applications of Flexible Auto…:

Flexible automation is ideal for medium demand with frequent product changes and variety, applied in industries like food/textile/paint manufacturing, industrial robotics, CNC machining, and warehouse automation.

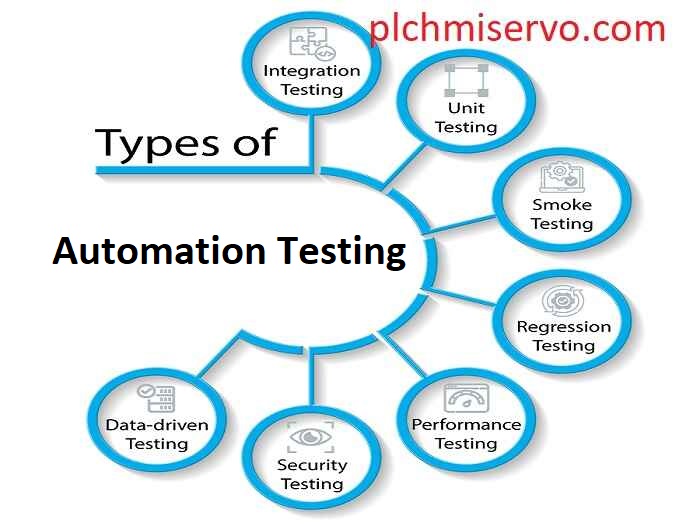

Different types of testing in automation

Companies must utilize the appropriate type of automated testing methodology, as it can help detect flaws, bugs, and other issues that impact the quality of the software product. The different types of automation testing are as follows:

1. Unit Testing: This is the initial type of automated testing. It entails examining individual software units or components. Developers typically perform this during the development phase, allowing them to identify problems early on. Unit testing verifies the code’s accuracy and functionality, and helps catch any defects before integrating it with other components.

2. Integration Testing: This automated testing checks how different software components interact and work together. It helps identify issues that may arise when integrating different parts of the software. Ensuring the components communicate and function properly together is crucial.

3. Functional Testing: This tests if the software product meets specific requirements and functions as intended from the user’s perspective. It verifies the product works correctly and satisfies user needs.

4. Regression Testing: After making changes to the software, this testing ensures the modifications did not introduce new defects. It confirms the product still functions properly after updates or revisions.

5. Performance Testing: This evaluates how the software performs under different workloads and conditions. It identifies any performance-related issues or limitations the product may have.

6. Security Testing: This checks for potential security vulnerabilities in the software that could be exploited. Ensuring the product is secure against attacks is vital.

7. Usability Testing: This examines the user-friendliness and accessibility of the software interface and experience. It identifies any usability issues that could hinder users.